Table Of ContentV-

'K-

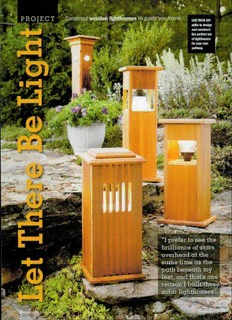

PROJECT '^^¿onstruct wooden lighthouses to guide youyhome

USE YOUR DIY

ir

skills to design

and construct

the perfect set

of lighthouses

for your own

pathway

i'W«'.A.!*4..

•^'^ •-.d'-

^-T^j;^^

"I prefer to see the

brilliance of stars

overhead at the

same time as the

¡path beneath my

feet, and that's one I

reason I built these'

'^I'^r lighthouses"

f

by DON ROSS

O

N MANY A moonless and overcast night, I've stumbled my way up the pathway from

my driveway to the front door. I live in rural Ontario—a streetlight-free zone—^but I've

seen the quest for yard lighting carried lo an extreme, with pathways looking more

like airport runways than simple country yards. I prefer to see the brilliance of stars

overhead at the same time as the path beneath my feet. That's one reason I built these

solar lighthouses. • When designing the projects, I wanted to blend in the styles with the exterior features

of my riverside home. I used western red cedar because it's pleasing to look at and weather-resistant. I

purchased a few feet of clear M"-thick boards in 10", 8" and 6" widths to build four variations of the light-

houses. • You'll notice there is no materials list for this project, just guidelines for four different designs,

because the specific dimensions and shapes depend on the solar fixtures you use and your own taste.

your tablesaw, cutting it to about 5%" bouom and lop of the box respec-

wide. Refine outside edges ox\ the tively, leaving a 4'/'"-taIl space for the

Jointer, creating a finished width of light to shine through. The height of

5". From this board, cul four 14'-long this space will depend on ihe height

and four 4"-long side-panel pieces. of your fixture.

Use weatherproof wood glue and 2" From ihe remaining length of the

galvanized or stainless-steel finish- 5"-wide stock, cut three 5" square

ing nails to assemble the lighthouse, pieces, one each for the inner box

using the %" x %" quarter-round cor- top, the base and the upper spacer.

ner strips to form the outside corners. The upper spacer needs a hole in the

Put ihe 14" and 4" side panels at the centre, just large enough to accom-

4 '/i" tall opening

(or whatever matches

your light fixture) top cap

1

'S

TOP VIEW

DESIGN #1: RISE AND SHINE

THIS [.iGHTHoust: ALLOWS the beams to holes required here for

shine out from all four sides. It has an solar charging wire

outside framework of shop-milled '/"

X Vi" quarter round, made especially

for the job from a IZVi" length of 1x6

western red cedar. Run the outside

edges oí the lull-width board over a

1 " roundover bit on a table-mounted

J L

router, cutting off the routed edges

in 'X"-wide strips before routing and

sawing again to remove more strips.

(I made a couple of extras from the

remaining wood, to be used for

parts of another lighthouse design,}

Smooth the saw-cut edges wiih a lew

passes of medium-grit sandpaper on a 22 Vi"

sanding block.

Next, make the side panels by run-

ning an 8' length of 1x6 cedar across SIDE VIEW

CHW SUMMER 2008 29

modate the light base shaft on the this cap also needs to be routed with allow the wire for the remote char-

fixture you're using. This spacer will a straight bit, creating rabbets around ger to extend down the quarter-round

eventually be nailed inside the top the edge that are %" deep and '/" wide. frame, exiting ihc lighthouse ir(tm a

section of the lightliousc (recosst'd This recess allows the inside box cap small hole in the base.

slightly for appearance), but not just to sit within the lighthouse itself. After Both the top cap and base oí the

yet; wait until the inside box cap (on this part is glued in place, it seals out lighthouse are 8" square. The top edges

which ihc inverted clear shade of the rain and melting snow. of these two parts need to be rounded

lighi rests) is in place. With the cap installed, inserí the over with a table-mounted router.

The inside box cap is 5'/i" square, light into the hole in the underside Glue and nail the previously cut 5"

cut irom a piece of 1x6 cedar. The of the upper spacer, then push down square spacers centred to the top of

light shade rests on this cap, but first the assembly into the lighthouse from the base piece and on the underside

you should paint the wood white to above. The wire ihat goes from the of the top cap. Remember to run the

better reflect the light. lamp to the solar charging unit needs wire out ol the hole in the base piece

For the best appearance, pass all a tiny hole at one corner of the upper before nailing it down. Set the top cap

four edges of thf top cap across a X" spacer and through the same corner in place without glue so you can ser-

routf r roundover bit. The underside of oí the inside box cap. These holes vice the light when needed.

date the shaft of an u[)ward-facing lighl For a more refined look, round-

fixture (as opposed to the downward over the edges of the top and bottom

facing fixture in the "Rise and Shine" caps. Again, you'll need to bore a hole

design). The upper spacer, painted white through the bottom assembly for wires

for reflectivity, is glued and nailed into that lead from a charger to the lamp.

the tops of the lO'A" side panels. Add a coat ol white paini to the upper

Continue by cutting the inner box spacer to reflea the light better. Install it

top, upper spacer and inner base to 5'Á" through the top of the lighthouse while

X 5'/5" from 1x6 stock. Two of these parts it's open, resting on the top of the lamp

are fixed to the centre of the 9" square shield. This arrangement keeps light-

base and the underside ol the top cap. attracted insects out of the lamp sliield

While you could get away without and also allows for easy servicing when

using spacers, they do add rigidity. you need to remove the top cap.

5 VJ"—^ 4 V:" tall opening

l)^ (or whatever matches

your light fixture)

DESIGN #2: TWO SIDED

THIS LIGHTHOUSE IS similar to the

first design, but a little easier to build

because it's open on two sides, not

TOP VIEW

four. Cut the two opposht' laces from

1x8 cedar hoard, each finished to 18"

long X 7" wide. Then cut the other two

sides from a 1x6 board, with two lO'/í" holes required here for

X 'i'A" bottom pieces and two 3" x 5'Á" solar charging wire

upjier pieces. Assemble these parts

with weatherproof glue and 2"-long

galvanized or stainless-steel finishing

nails, creating a light opening that's

4'/" tail on two opposing sides,

The inside box cap measures 5'Á"

X 7". It's not square because only two

edges overhang the base. The 51^'edges

need to be rounded over; the 7" ends

need to be square so they fit between

enclosed sides. The underside of this cap

needs to be recessed with a '/>"-deep x

V5"-wide rabbet on the 5'A"-lang edges.

Bore a hole in the centre to accommo-

SIDE VIEW Side

30 CHW SUMMER 2008 Canadian homeworkshop,com

top cap

T 4 '/î" tall opening quarter round

(or whatever matches corner strips

your light fixture Inner box

8" top

holes required here for

solar charging wire

DESIGN #3: GLORIOUS GLOW

more of a glow

THIS VERSKIN CASTS

around it, rather than aaually lighting a

path. The stitied openings let some light

escape, but it's faint, creating a pleasant SiDEViEW '/»"•deep X Vî"-wide grooves on 1" centres

trail marker. The overall dimensions are

"When designing the projects, I wanted to

18" lali and 8" square.

Cut the slits thai form the opening blend in the styles with the exterior features

In two phases'—some from the back

of my lakeside home"

and others from the front—both using

a '/" straight router bit. Begin on ihe

back, where you want the slits to go all

the way through the panels. I milled

mine 4'Ä" long, to match the size of the

lamps I used. Slop strips clamped across

the panels regulate the Icngih of the

grooves automatically. I made the spac-

ing regular with a guide strip damped

to the wood, moving it in I " increments

to create subsequent grooves.

After the inside short grooves are

cut, turn the panels over and repeat

the process on the front, except this

time, cut the grooves the full length of

the panels on a router table. Where the

inside and outside grooves meet, con-

tinuous openings are created through

the full thickness of the panels, letting

light escape.

A total of lour inside spacers are

required—the inner base, the lower

spacer, the upper spacer and the inner open slits. Thf top cap and base arc with a small hole bored through the

box lop—each 67/ x 6'Á". The upper 9" square in my design, with edges bottom assembly for the charging

spacer needs a hole cut in ihe centre chamfered to half the thickness of ihe wire.

where the shalt of tfie lamp fits. Nail caps using a 45" bit in the router. The For decoration, 1 fastened a 6'/j"

il into the lighthouse with its lower inner box top and inner base need to square of wood on top of the top cap

surface flush to the top ends of the be fastened to the top cap and base, after rounding its edges with a router.

CHW SUMMER 2008 31

DESIGN #4: IN THE SPOTLIGHT

THIS FINAL LIGHTHOUSE is designed to

lighi up an object, such as a statue, rath-

er than to mark a path. The shape uses

two side panels that measure 30" x 6'A".

and two that are 30" x 5'i".

The two wider side panels have edges

chamfered using a 45" router bil. This

chamfer begins 5" from the top of the

panel and ends 6" trom the bottom. Each

wide

panel also has holes bored 8" down from SIDEVIEW

side panei

the top. The hole size needs to accom-

DIY Design

modate the diameter of the housing of

the spotlight you will be using.

1 trimmed the top with a scrap uf

moulding I had on hand. I continued THIS IS A true DIY project because the

the chamfered theme around both the final design is up to you. It has to be.

top and bottom cap. As with all the There are plenty of lamps, solar cells and

otlier lighthouses, there's a series ol charging units on the market, but I could

inside spacers, with a hole in the bot- not find a specific kit with components

tom for the charging wire. for walkway lights. That's why I cannibal-

ized store-bought lights, rummaged in

FIT AND FINISH my shop for metal and plastic housings,

LEFT UNI-INISHED, THE western red and often snipped and soldered wiringto

cedar eventually weathers to grey. To reassemble the desired lamps, circuits

keep the cedar glow as long as possible, and chargers. You'll need to do the same,

I treated all surlaces ot the walkway and that will affect how you put the wood-

lights with Cabot's clear cedar finish. en parts of the project together, too.

Place and angle the solar collectors The bottom line: decide what style

where they will get as much full sun of walkway lighthouse will fit your hoti •

as possible. If the wires are at risk from or cottage, do a rough drawing, then go

traflic, an errant garden spade or pesky shopping for the lights to make the proj-

chipmunk, consider sheathing them in ect work. Prepare to be flexible in your

an old length of garden hose. design as you accommodate the dimen-

Then, come some starry evening, sions of the essential parts of the lamp. REMOTE SOLAR charging units provide

your lights will be ready to guide you, You'll find that a model with a remote more flexibility In your design

not blind you, as they guide you charging unit rather than a built-in one is

home. O best suited for this application. It allows more freedom of design and placement, as

well as better charging and battery capacity than typically found in the fixtures with a

DON ROSS enjoys the gentle nightime glow of charger built into the top of the unit.

his new solar lighthouses.

32 CHW SUMMER 2008 canadianhonieworhsfiOp.com