Table Of ContentInstallation Instructions

Original Instructions

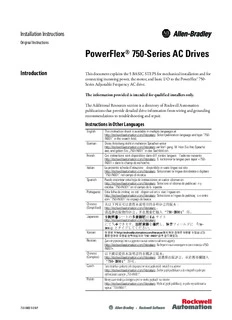

PowerFlex® 750-Series AC Drives

Introduction

This document explains the 5 BASIC STEPS for mechanical installation and for

connecting incoming power, the motor, and basic I/O to the PowerFlex® 750-

Series Adjustable Frequency AC drive.

The information provided is intended for qualified installers only.

The Additional Resources section is a directory of Rockwell Automation

publications that provide detailed drive information from wiring and grounding

recommendations to troubleshooting and repair.

Instructions in Other Languages

English This instruction sheet is available in multiple languages at

http://rockwellautomation.com/literature. Select publication language and type “750-

IN001“ in the search field.

German Diese Anleitung steht in mehreren Sprachen unter

http://rockwellautomation.com/literature zur Verfügung. Wählen Sie Ihre Sprache

aus, und geben Sie „750-IN001“ in das Suchfeld ein.

French Ces instructions sont disponibles dans différentes langues à l’adresse suivante:

http://rockwellautomation.com/literature. Sélectionner la langue puis taper «750-

IN001 » dans le champ de recherche.

Italian La presente scheda d’istruzione è disponibile in varie lingue sul sito

http://rockwellautomation.com/literature. Selezionare la lingua desiderata e digitare

“750-IN001“ nel campo di ricerca.

Spanish Puede encontrar esta hoja de instrucciones en varios idiomas en

http://rockwellautomation.com/literature. Selecione el idioma de publicación y

escriba “750-IN001“ en el campo de búsqueda.

Portuguese Esta folha de instruções está disponível em várias línguas em

http://rockwellautomation.com/literature. Seleccione a língua de publicação e entre

com “750-IN001“ no espaço de busca.

Chinese 从以下网页可以获得本说明书的多种语言的版本:

(Simplified) http://rockwellautomation.com/literature 。

请选择出版物的语言,并在搜索栏输入“750-IN001”印。

Japanese 本説明書シートの多言語版はWebサイト

http://rockwellautomation.com/literature

にて入手できます。出版言語を選択し、検索フィールドに 「750-

IN001」とタイプしてください。

Korean (cid:14504) (cid:11193)(cid:10605) (cid:11956) http://rockwellautomation.com/literature(cid:14084)(cid:12880) (cid:14112)(cid:10528) (cid:14060)(cid:14056)(cid:10640) (cid:12768)(cid:14301)(cid:18068) (cid:13132)(cid:14524)(cid:13289)(cid:9212)(cid:9240).

(cid:16080)(cid:17476) (cid:14060)(cid:14056)(cid:14196) (cid:14420)(cid:18249)(cid:14456) (cid:12884)(cid:16913)(cid:18060)(cid:13345)(cid:13328)(cid:14168) "750 - IN001"(cid:7604)(cid:12797) (cid:18040)(cid:9744)(cid:14084)(cid:14524)(cid:9240).

Russian Данное руководство на других языках можно найти по адресу

http://rockwellautomation.com/literature. Выберите язык и введите в окно поиска «750-

IN001».

Chinese 以下網頁提供本說明書的多國語言版本:

(Complex) http://rockwellautomation.com/literature. 請選擇出版語言,並於搜尋欄鍵入

“750-IN001”即可。

Czech Tato stránka s pokyny je k dispozici ve více jazykových verzích na adrese

http://rockwellautomation.com/literature. Zvolte jazyk publikace a do vstupního pole pro

vyhledávání zadejte „750-IN001“.

Polish Niniejsza instrukcja dostępna jest w wielu językach na stronie

http://rockwellautomation.com/literature. Wybrać język publikacji, w polu wyszukiwania

wpisać “750-IN001”.

750-IN001I-EN-P

PowerFlex 750-Series AC Drives

PowerFlex 750-Series AC Table of Contents

Drives

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Commonly Used Tools

Installation and Service Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Step 1: Read the General Precautions

Qualified Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Personal Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Product Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Class 1 LED Product. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Step 2: Prepare for Installation

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Drive Frame 1…7 Rating Cross-References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Drive Frame 8…10 Rating Cross-References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CE Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Access Panels, Covers, and Doors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Minimum Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Mounting Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Motor Overload Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Short Circuit Current Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Step 3: Lift and Mount the Drive

Drive Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Recommended Mounting Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Attach Lifting Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Release Drive Cabinet Frame 8 and Larger Shipping Skid. . . . . . . . . . . . . . . . . . . 31

Remove Drive Cabinet Lifting Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Install Exhaust Hood. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Install Cabinet Blower Assembly and Exhaust Hood . . . . . . . . . . . . . . . . . . . . . . . 33

Approximate Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Release Drive Assembly From Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Fiber-Optic Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Disconnect Drive Control Pod Wiring Connections . . . . . . . . . . . . . . . . . . . . . . . 69

Disconnect Wire Connections - No Drive Control Pod . . . . . . . . . . . . . . . . . . . . 71

Disconnect Control and Power Wire Harnesses - AC Input Drives . . . . . . . . . . 73

Disconnect Control and Power Wire Harnesses - Common DC Input Drives 74

Prepare the Roll-Out Cart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Remove Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Remove DC Back Bus Guard - Common DC Input Drives . . . . . . . . . . . . . . . . . 87

Reinstall Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Step 4: Power Wiring

Grounding Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Recommended Grounding Scheme. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Shield Termination - SHLD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

RFI Filter Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Power Cable Types Acceptable for 200…600 Volt Installations . . . . . . . . . . . . . . 90

Wire Recommendations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Motor Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Terminal Block Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

2 Rockwell Automation Publication 750-IN001I-EN-P - March 2012

PowerFlex 750-Series AC Drives

Three-Phase Terminal Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Frame 1…7 AC Input Power Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Frame 5…7 Common DC Input Terminal Locations . . . . . . . . . . . . . . . . . . . . . . . 96

Frame 5…7 Common DC Input Power Terminals. . . . . . . . . . . . . . . . . . . . . . . . . . 98

Frame 8…10 Bus Bar Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Frame 8…10 Power Wiring Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Frame 8…10 Power Terminal L-Brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Recommended Motor Cable Spacing - Frame 8 and Larger . . . . . . . . . . . . . . . . 103

Drive, Fuse & Circuit Breaker Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Input Contactor Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Output Contactor Precaution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Bypass Contactor Precaution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Applying and Removing Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Drive Power Jumper Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

MOV, AC EMI Capacitor, and Common Mode Capacitor Circuits . . . . . . . . 119

Frame 2…5 Power Jumper Screw Removal and Storage . . . . . . . . . . . . . . . . . . . . 122

Frame 1, 6, and 7 Power Jumper Wire Removal and Storage. . . . . . . . . . . . . . . . 123

Frame 8…10 Drive Assembly Jumper Removal and Storage . . . . . . . . . . . . . . . . 126

Step 5: I/O Wiring

I/O Terminal Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Access Drive Control Pod. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

PowerFlex 753 Main Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

PowerFlex 755 Main Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

AC Input Drive Control and Power Terminal Block. . . . . . . . . . . . . . . . . . . . . . . 139

Common DC Input Drive Control and Power Terminal Blocks. . . . . . . . . . . . 140

Control Transformer Connections - Common DC Input Drives . . . . . . . . . . . 143

Uninterruptible Power Supply Connections - Common DC Input Drives. . . 144

120/240V AC Power Supply Connections - Common DC Input Drives. . . . 145

Hardware Enable Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Safety Enable Circuitry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

PowerFlex 755 Fiber Optic Interface Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Drive Device Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Option Module Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

I/O Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Safe Torque Off Option Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Safe Speed Monitor Option Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Auxiliary Power Supply Option Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

DeviceNet Option Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

ControlNet Option Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

20-COMM Carrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Single Incremental Encoder Option Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Dual Incremental Encoder Option Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Universal Feedback Option Module - 755 Drives Only. . . . . . . . . . . . . . . . . . . . 174

Motor Power Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Feedback Device Resolution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Motor Feedback Wiring Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Control Pod Cable Routing - Frames 8…10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Rockwell Automation Publication 750-IN001I-EN-P - March 2012 3

PowerFlex 750-Series AC Drives

PowerFlex 755 Drives with

Hardware Overview

Cabinet Options Power Disconnect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Contactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Reactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Terminal Blocks and Other Cabinet Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Enclosure Options

NEMA/UL Type 1 Enclosure - 2500 MCC Style Cabinet. . . . . . . . . . . . . . . . . 190

Step 1: Read the General Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .190

Step 2: Prepare for Installation

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

CE Conformity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Access Panels, Covers, and Doors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Minimum Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Mounting Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Short Circuit Current Ratings for Drives with Cabinet Options. . . . . . . . . . . . 194

Step 3: Lift and Mount the Drive

Drive Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Recommended Mounting Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Attach Lifting Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

Release Frame 8…9 Shipping Skid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Frame 8…9 Lifting Angle and Exhaust Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Approximate Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

Step 4: Power and Control Wiring

Wiring Only Bay Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Cabinet Options Bay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Input Power Circuit Breakers and Disconnect Switches. . . . . . . . . . . . . . . . . . . . 210

Control Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Power Wiring Schematic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Integrated Motion Drives

Configuring Option Modules for Integrated Motion

Supporting Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

4 Rockwell Automation Publication 750-IN001I-EN-P - March 2012

PowerFlex 750-Series AC Drives

Additional Resources

The following table lists publications that provide general drive related

information.

Resource Description

PowerFlex 750-Series AC Drives Programming Manual, Provides detailed information on:

publication 750-PM001 • I/O, control, and feedback options

• Parameters and programming

• Faults, alarms, and troubleshooting

PowerFlex 750-Series AC Drives Technical Data, Provides detailed information on:

publication 750-TD001 • Drive specifications

• Option specifications

• Fuse and circuit breaker ratings

PowerFlex 20-HIM-A6 / -C6S HIM (Human Interface Provides detailed information on HIM components,

Module) User Manual, publication 20HIM-UM001 operation, features.

PowerFlex 750-Series AC Drives Hardware Service Manual Provides detailed information on:

- Frame 8 and Larger, publication 750-TG001 • Preventive maintenance

• Component testing

• Hardware replacement procedures

PowerFlex 755 Drive Embedded EtherNet/IP Adapter User These publications provide detailed information on

Manual, publication 750COM-UM001 configuring, using, and troubleshooting PowerFlex

750-Series communication option modules and adapters.

PowerFlex 750-Series Drive DeviceNet Option Module User

Manual, publication 750COM-UM002

PowerFlex 7-Class Network Communication Adapter User

Manuals, publications 750COM-UMxxx

PowerFlex 750-Series Safe Torque Off User Manual, These publications provide detailed information on

publication 750-UM002 installation, set up, and operation of the 750-Series safety

option modules.

Safe Speed Monitor Option Module for PowerFlex

750-Series AC Drives Safety Reference Manual, publication

750-RM001

Wiring and Grounding Guidelines for Pulse Width Provides basic information needed to properly wire and

Modulated (PWM) AC Drives, publication DRIVES-IN001 ground PWM AC drives.

PowerFlex AC Drives in Common Bus Configurations, Provides basic information needed to properly wire and

publication DRIVES-AT002 ground PWM AC drives using a common bus.

Safety Guidelines for the Application, Installation and Provides general guidelines for the application,

Maintenance of Solid State Control, publication SGI-1.1 installation, and maintenance of solid-state control.

A Global Reference Guide for Reading Schematic Provides a simple cross-reference of common schematic/

Diagrams, publication 100-2.10 wiring diagram symbols used throughout various parts of

the world.

Guarding Against Electrostatic Damage, publication 8000- Provides practices for guarding against Electrostatic

4.5.2 damage (ESD)

Product Certifications website, http://ab.com Provides declarations of conformity, certificates, and other

certification details.

Rockwell Automation Publication 750-IN001I-EN-P - March 2012 5

PowerFlex 750-Series AC Drives

Commonly Used Tools Installation and Service Tools

IMPORTANT Care must be taken to ensure that tools and/or hardware components do not fall into

open drive assemblies. Do not energize the drive unless all loose tools and/or hardware

components have been removed from the drive assemblies and enclosure.

This list covers the tools needed for drive installation.

Tool Description Details

ESD-protected place of work Working surface, Floor covering, seat and ground connections

ESD-protective clothing Wrist wrap, shoes, overall clothing (coat)

Multi meter Digital multi meter, capable of ac and dc voltage, continuity, resistance,

capacitance measurements, and forward diode bias tests. Fluke model 87 III or

equivalent.

Allen socket wrench 4 mm, 5 mm

Allen socket wrench extension 254 mm (10 in.)

Flat nose screw driver 5 mm (0.19 in.), 6.4 mm (0.25 in.), 9.5 mm (0.375 in.), #1, #2

Hexalobular screw driver/bit #15, #20, #25, #40, #45

Hexagonal socket wrench 7 mm, 8 mm, 10 mm, 12 mm, 13 mm, 17 mm, 18 mm

Combination wrench 10 mm, 17 mm

Phillips® screw driver/bit (1) #2, 492-C

Pozidriv® (1) #2

Torque wrench 1...12 N•m (8.8…106 lb•in)

Torque wrench 6...50 N•m (53…443 lb•in)

Roll-out cart 20-750-CART1-F8

Note: The roll-out cart is required to remove the drive assembly from the

enclosure.

(1) Phillips and Pozidriv are registered trademarks of the Phillips Screw Company.

6 Rockwell Automation Publication 750-IN001I-EN-P - March 2012

PowerFlex 750-Series AC Drives

Step 1: Read the General Qualified Personnel

Precautions

ATTENTION: Only qualified personnel familiar with adjustable frequency AC drives and

associated machinery should plan or implement the installation, start-up and

subsequent maintenance of the system. Failure to comply may result in personal injury

and/or equipment damage.

Personal Safety

ATTENTION: To avoid an electric shock hazard, verify that the voltage on the bus

capacitors has discharged completely before servicing.

Frames 1…7: Measure the DC bus voltage at the Power Terminal Block by measuring

between the +DC and -DC terminals (see Figure 50 and Figure 51 for location), between

the +DC terminal and the chassis, and between the -DC terminal and the chassis. The

voltage must be zero for all three measurements.

Frame 8…10: Measure the DC bus voltage at the DC+ and DC- TESTPOINT sockets on the

front of the power module (see Figure 54 for location).

ATTENTION: Hazard of personal injury or equipment damage exists when using bipolar

input sources. Noise and drift in sensitive input circuits can cause unpredictable changes

in motor speed and direction. Use speed command parameters to help reduce input

source sensitivity.

ATTENTION: Risk of injury or equipment damage exists. DPI or SCANport host products

must not be directly connected together via 1202 cables. Unpredictable behavior can

result if two or more devices are connected in this manner.

ATTENTION: The drive start/stop/enable control circuitry includes solid state

components. If hazards due to accidental contact with moving machinery or

unintentional flow of liquid, gas or solids exists, an additional hardwired stop circuit

may be required to remove the AC line to the drive. An auxiliary braking method may be

required.

ATTENTION: Hazard of personal injury or equipment damage due to unexpected

machine operation exists if the drive is configured to automatically issue a Start or Run

command. Do not use these functions without considering applicable local, national

and international codes, standards, regulations or industry guidelines.

Rockwell Automation Publication 750-IN001I-EN-P - March 2012 7

PowerFlex 750-Series AC Drives

Product Safety

ATTENTION: An incorrectly applied or installed drive can result in component damage

or a reduction in product life. Wiring or application errors such as under sizing the

motor, incorrect or inadequate AC supply, or excessive surrounding air temperatures

may result in malfunction of the system.

ATTENTION: This drive contains ESD (Electrostatic Discharge) sensitive parts and

assemblies. Static control precautions are required when installing, testing, servicing or

repairing this assembly. Component damage may result if ESD control procedures are

not followed. If you are not familiar with static control procedures, reference Guarding

Against Electrostatic Damage, publication 8000-4.5.2 or any other applicable ESD

protection handbook.

ATTENTION: Configuring an analog input for 0-20 mA operation and driving it from a

voltage source could cause component damage. Verify proper configuration prior to

applying input signals.

Class 1 LED Product

ATTENTION: Hazard of permanent eye damage exists when using optical transmission

equipment. This product emits intense light and invisible radiation. Do not look into

module ports or fiber optic cable connectors.

8 Rockwell Automation Publication 750-IN001I-EN-P - March 2012

PowerFlex 750-Series AC Drives

Step 2: Prepare for Catalog Number Explanation

Installation

1…3 4 5 6 7 8…10 11 12 13 14 15 16 17 18

20G 1 A N D 248 A A 0 N N N N N -LD-P3-P11…

a b c d e f1…f4 g h Cabinet Options (21G)

a e

Drive Voltage Rating

Code Type Code Voltage

20F PowerFlex 753 C 400V AC/540V DC

20G PowerFlex 755 D 480V AC/650V DC

21G PowerFlex 755 Drive with Options E 600V AC/725V DC

F 690V AC/932V DC (not UL listed)

b

Future Use f1 f2

ND Rating ND Rating

c

400V, 50 Hz Input 480V, 60 Hz Input

Input Type Frame Frame

Code Description Frames EnclosureCode EnclosureCode

Code Amps kW Code Amps Hp

1…5, B,J, K, P, B,J, K, P,

1 AC & DC Input w/Precharge F G N R F G N R

8…10 L W,Y L W,Y

4 DC Input w/Precharge 5…10 2P1 2.1 0.75 2P1 2.1 1

A AC Input w/Precharge, no DC Terminals 6…8 3P5 3.5 1.5 3P4 3.4 2

Frames 1…4, Code 1 also provides the functionality of DC input with 5P0 5.0 2.2 5P0 5.0 3

Precharge. Frames 5 & larger, Code 4 is required for DC input with 1 1

8P7 8.7 4 2 2 2 8P0 8.0 5 2 2 2

Precharge. The optional DC Bus Bar kit (20-750-DCBB1-Fx) is

available for Frames 6…7 ACinput drives requiring DC bus 011 11.5 5.5 011 11 7.5

terminals. 015 15.4 7.5 014 14 10

022 22 11 022 22 15

d

030 30 15 027 27 20

Enclosure 037 37 18.5 3 3 3 034 34 25 3 3 3

Code Description Frames 043 43 22 040 40 30

R IP20, NEMA/UL Type Open, Frame 1 1 060 60 30 – 4 – 052 52 40 – 4 –

4 4 4 4

F § Flange (NEMA/UL Type 4X/12 back) 2…5 072 72 37 065 65 50

5 5

G IP54, NEMA/UL Type 12 2…7 085 85 45 077 77 60

5 5 5 5

N ‡ IP20/IP00, NEMA/UL Type Open 2…7 104 104 55 096 96 75

IP20, NEMA/UL Type 1, 140 140 75 125 125 100

B 600 mm (23.6 in.) Deep, 8…10 6 6

170 170 90 156 156 125

Standard Cabinet Color (RAL 7032) 6 6

205 205 110 186 186 150

IP54, NEMA Type 12,

J 800 mm (31.5 in.) Deep, 8…10 260 260 132 § 248 248 200 §

Standard Cabinet Color (RAL 7032) 302 302 160 302 302 250

7 7

IP54, NEMA Type 12, 367 367 200 7 361 361 300 7

K Δ 2500 MCC Style Cabinet & Options 8…10 456 456 250 – 415 415 350 –

w/MCC Power Bus,800 mm (31.5 in.) Deep,

Standard Cabinet Color (RAL 7032) 460 460 250 430 430 350

IP20, NEMA/UL Type 1, 540 540 315 485 485 400

L 800 mm (31.5 in.) Deep, 8…10 567 567 315 545 545 450

Standard Cabinet Color (RAL 7032) 8 8 Δ 8 8 Δ

650 650 355 617 617 500

IP20, NEMA/UL Type 1,

P Δ 2500 MCC Style Cabinet & Options 8…10 750 750 400 710 710 600

w/MCC Power Bus,800 mm (31.5 in.) Deep, 770 770 400 740 740 650

Standard Cabinet Color (RAL 7032)

910 910 500 800 800 700

IP20, NEMA/UL Type 1, – – – – – –

1K0 1040 560 960 960 800

W Δ w/MC2C5 0P0o wMeCrC B Sutsy,le8 0C0a bminmet ( 3&1 O.5p tinio.)n Dseep, 8…10 1K1 1090 630 9 9Δ 1K0 1045 900 9 9 Δ

CenterLine 2100 Gray (ASA49) 1K2 1175 710 1K2 1135 1000

IP54, NEMA Type 12, 1K4 1465 800 1K3 1365 1100

Y Δ 2500 MCC Style Cabinet & Options 8…10 1K5 1480 850 1K4 1420 1250

w/MCC Power Bus,800 mm (31.5 in.) Deep,

CenterLine 2100 Gray (ASA49) 1K6 1590 900 10 1K5 1525 1350 10

10 10

§ For Frames 6…7 a User Installed Flange Kit is available to convert a 2K1 2150 1250 Δ 2K0 2070 1750 Δ

Code N drive that provides a NEMA/UL Type 4X/12 back. § For Frames 6…7 a User Installed Flange Kit is available to convert a § For Frames 6…7 a User Installed Flange Kit is available to convert a

‡ Frames 2…5 are IP20, Frames 6…7 are IP00. Code N drive that provides a NEMA/UL Type 4X/12 back. Code N drive that provides a NEMA/UL Type 4X/12 back.

ΔAvailable as a drive with options (21G). ΔAvailable as a drive with options (21G). ΔAvailable as a drive with options (21G).

Rockwell Automation Publication 750-IN001I-EN-P - March 2012 9

PowerFlex 750-Series AC Drives

Catalog Number Explanation (continued)

f3 f4 PowerFlex 755 w/Options (21G) - Required Selections

ND Rating ND Rating Code Option Type Frames

600V, 60 Hz Input 690V, 60 Hz Input (not UL listed) LD Light Duty

Frame Frame ND Normal Duty System Overload 8…10

Duty Cycle

Code Amps Hp Enclosure Code Code Amps kW Enclosure Code HD Heavy Duty

B,L J, F G N WK,, PY, R B,L J, F G N WK,, PY, R P3 InputC Tirhceuritm Barle Makaegrnetic Power

295 295 300 265 265 250 Input Non-Fused Molded Disconnect or 8…10

P5 Wiring Only Bay

355 355 350 330 330 315 Case Disconnect Switch

395 395 400 370 370 355 P14 Wiring Only Bay

8 – – – 8 Δ – 8 – – – 8 Δ –

435 435 450 415 415 400 Only one option of this type may be selected.

460 460 500 460 460 450

510 510 500 500 500 500

595 595 600 590 590 560 PowerFlex 755 w/Options (21G) - Additional Selections

630 630 700 650 650 630

Code Option Type Frames

760 760 800 710 710 710

9 9 Δ 9 9 Δ P11 Input Contactor

825 825 900 765 765 750 Contactors § 8

– – – – – – – – P12 Output Contactor

900 900 950 795 795 800

L1 3% Input Reactor

980 980 1000 960 960 900 8…10

L2 3% Output Reactor

1K1 1110 1100 10 10 1K0 1040 1000 10 10 L3 5% Input Reactor Reactors

1K4 1430 1400 Δ 1K4 1400 1400 Δ 8

L4 5% Output Reactor

ΔAvailable as a drive with options (21G). ΔAvailable as a drive with options (21G).

P20 1200 Amp Bus

MCC Power Bus

P22 2000 Amp Bus 8…10

Capacity

g P24 3000 Amp Bus

Filtering and CM Cap Configuration ♦ P30 UPS Control Bus, DC Input UPS Control Bus 8…10

w/Precharge only

Code Filtering Default CM Cap Connection

Only one option of this type may be selected.

A Yes Jumper Removed

§ Contactor options are not available for systems with MCC power bus.

J Yes Jumper Installed

♦480V drives must select code "A." Jumpers are included for field

reconfiguration as desired.

h

Dynamic Braking &

Code Internal Resistor ♠ Internal Transistor ∇

A No Yes

N No No

♠Frames 1…2 only.

∇Standard on Frames 1…5, optional on 6…7.

&Not available on Frames 8…10, specify Code "N."

10 Rockwell Automation Publication 750-IN001I-EN-P - March 2012

Description:French. Ces instructions sont disponibles dans différentes langues à l'adresse Puede encontrar esta hoja de instrucciones en varios idiomas en .. Noise and drift in sensitive input circuits can cause unpredictable changes.