Table Of ContentM A K E B U I L D H A C K C R E AT E

hsmag.cc January 2020 Issue #26

Building

TT

AA

HH

WW a kiln

+ Melting glass with

a Raspberry Pi

Jan.2020

Issue #26 £6

CIRCUIT

PYTHON

SOLDERING

WITH GAS

??

RR

EE

PICKING TT

NN

AN IMPACT RRII

PP

DRIVER

mate

SMEAWCIHNINGES rFeipnldic tahteo ru flotir 2020

KIM

Arduino CNC

data log milling FREEBURN

Talks autonomous racing robots

Store info on your microcontroller Carve out objects automatically

PAINTING CANDLES HAIR-DRYERS INFILL

191029_AWAIT_HS_UK.indd 1 10/10/19 4:43 PM

WELCOME

EDITORIAL

Editor

Ben Everard

Welcome to [email protected]

Features Editor

Andrew Gregory

HackSpace magazine

[email protected]

Sub-Editors

David Higgs, Nicola King

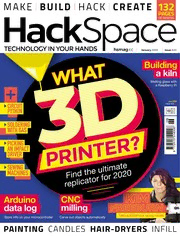

Automatic replicators have been the stuff of science fiction DESIGN

Critical Media

for generations. For a decade or so now, 3D printers have

criticalmedia.co.uk

been on the verge of promising to make this a reality, but Head of Design

Lee Allen

they’ve been fiddly and hard to get to work reliably at an

Designers

affordable price. In the last year or two, it feels like there’s Ty Logan

been a real shift, not in the underlying technology, but in its Photography

Brian O’Halloran, Nikolai Linares

ease of use. Non-technical (or moderately technical) users

CONTRIBUTORS

can now buy affordable

Lucy Rogers, Drew Fustini,

In the last year or two, it feels like there’s

3D printers and use them Jo Hinchliffe, Jon Rusho,

Mayank Sharma, Andrew Lewis,

been a real shift, not in the underlying reliably, and that’s a huge Glenn Horan, Gareth Branwyn, Les

Pounder, Marc de Vinck, Poppy

technology, but in its ease of use step. Of course, it hasn’t Mosbacher, Demetrio Pinna

happened uniformly PUBLISHING

Publishing Director

across the industry, so in this issue, we’re looking at the best

Russell Barnes

3D printers around, and what experiences people have had [email protected]

Advertising

in their homes and workshops. Could 2020 be the year 3D

Charlie Milligan

printing goes mainstream? [email protected]

DISTRIBUTION

BEN EVERARD Seymour Distribution Ltd

2 East Poultry Ave,

Editor [email protected] London EC1A 9PT

+44 (0)207 429 4000

SUBSCRIPTIONS

Unit 6, The Enterprise Centre,

PAGE 48 Kelvin Lane, Manor Royal,

Got a comment, Crawley, West Sussex, RH10 9PE

question, or thought SUBSCRIBE To subscribe

abomuta HgaazciknSep?a ce TODAY 01293 312189

hsmag.cc/subscribe

get in touch at Subscription queries

hsmag.cc/hello [email protected]

GET IN TOUCH

This magazine is printed on

hackspace@ paper sourced from sustainable

raspberrypi.org forests. The printer operates an

environmental management system

h ackspacemag which has been assessed as

conforming to ISO 14001.

h ackspacemag HackSpace magazine is published

by Raspberry Pi (Trading) Ltd.,

Maurice Wilkes Building, St. John’s

ONLINE Innovation Park, Cowley Road,

Cambridge, CB4 0DS The publisher,

hsmag.cc editor, and contributors accept

no responsibility in respect of any

omissions or errors relating to goods,

products or services referred to or

advertised. Except where otherwise

noted, content in this magazine is

licensed under a Creative Commons

Attribution-NonCommercial-

ShareAlike 3.0 Unported (CC BY-NC-

SA 3.0). ISSN: 2515-5148.

3

Contents

126

SPARK LENS

06 33

06 Top Projects 34 What 3D printer?

What’s impressed us this month All the knowledge you need to choose your next replicator

16 Objet 3d’art 50 How I Made: Glass kiln controller

3D-printing: tastes good, will save the rainforest Monitor the temperature of molten glass

18 Meet the Maker: Kim Freeburn 56 In the workshop: Gold repair

Creator of accessible robotics company, PiBorg We try the ancient Japanese art of Kintsugi

22 Columns 60 Interview: Chan’nel Vestergaard

On the mutable magic of FPGAs How one self-taught maker is bringing science to the masses

24 Letters 68 Improviser’s Toolbox Hair-dryers

Your requests, rants, and recommendations What fun we can have with hot air and a fan

26 Kickstarting

Connect I2C devices to your desktop computer Tutorial

28 Hackspace Geekspace Gwinnett

Build a

Geeking out in Georgia (USA)

baby monitor

Cover Feature

AATT

HH

WW

RR?? 90 Big Brother is

EE

NNTT watching you

RRII

PP

Dfiisrscto3 ivnDe- rdp terhipnett hirne gcso usmlutsrmv oeufyn tihtye 18

34

4

CONTENTS

Direct from Shenzhen

USB power adapter

56

Interview

Chan’nel Vestergaard

106

114 Phenomenal USB power

with an itty-bitty price tag

73 FORGE

74 SoM CircuitPython

60 From self-taught Arduino tinkerer, to visiting

Use maths and code to generate waveforms MIT fellow, via shoes made from pineapple

76 SoM CNC routing

It’s time to put the metal to the plywood 116

80 Maker’s Toolbox: Impact drivers 113 FIELD TEST

We’re talking about torque

84 Tutorial Sewing machines 114 Direct from Shenzhen USB power manager

Get started with this makerspace stalwart Turn a puny 5 V into 30 V with this affordable doohickey

88 Tutorial Painting 116 Best of Breed

Protect and beautify your builds with paint Our favourite learn-to-solder kits

90 Tutorial Build a baby monitor 122 Can I Hack It?

Craft a surveillance device for your tiny human Get under the hood of a kids’ electronics kit

96 Tutorial OctoPrint 124 Review Gas-powered soldering iron

Set up control software for your 3D printer Take hardware hacking on the road with this portable tool

96

100 Tutorial Logging 126 Review Let’s Start Coding

Capture environmental data from an Arduino An accessible way into learning microcontrollers

106 Tutorial Open weather station 128 Review All About Circuits: Tools

Interpret open data with a simple IoT build Outsource your electronics calculations with this excellent website

110 Tutorial 3D print infills 129 Book Review Unix: A History and a Memoir

Give your prints structural strength A rose-tinted history of this ubiquitous computing platform

Some of the tools and techniques shown in HackSpace Magazine are dangerous unless used with skill, experience and appropriate personal protection equipment. While we attempt to guide the reader, ultimately you

are responsible for your own safety and understanding the limits of yourself and your equipment. HackSpace Magazine is intended for an adult audience and some projects may be dangerous for children. Raspberry

Pi (Trading) Ltd does not accept responsibility for any injuries, damage to equipment, or costs incurred from projects, tutorials or suggestions in HackSpace Magazine. Laws and regulations covering many of the topics

in HackSpace Magazine are different between countries, and are always subject to change. You are responsible for understanding the requirements in your jurisdiction and ensuring that you comply with them. Some

manufacturers place limits on the use of their hardware which some projects or suggestions in HackSpace Magazine may go beyond. It is your responsibility to understand the manufacturer’s limits.

5

Top Projects

REGULAR

6

SPARK

Giant LED

By Robert Fitzsimons hsmag.cc/OlgTmx

T his giant LED is completely pointless, but as a

great man once said, all art is quite useless. It

is, however, completely beautiful. Everything

is created by Robert, from the casting to the

handmade moulds, the only off-the-shelf parts being

the electronic components. He’s made a series of

videos documenting the process, showing a Zen-like focus on

perfectionism that we think shines through in the finished article.

In the first version, for example, the legs were made of 6 mm

copper tubing; in the final version, they’re cast resin with brass

welding rods embedded for strength and conductivity. To get

the right compromise of transparency and diffusion, Robert

has included 0.0075% zinc oxide (white pigment) into the resin

that makes up the LED bulb, and every aspect of the build has

undergone loads of tiny tweaks and modifications to get as close

to perfection as possible. This is a great build.

Left

Modelling the shape of the LED was easy (says

Robert): it’s just a sphere, a cylinder, and another

slightly larger cylinder, with a chunk taken off on

the cathode (short leg) side

7

Top Projects

REGULAR

Dragonfly

By Jack Spiggle hsmag.cc/xyEjKy

T his is a BEAM robot, which stands for

biology, electronics, aesthetics, and mechanics.

BEAM robots are characterised by extremely

simple circuitry, controlled directly by hardware and

reactions to sensors, rather than logic programmed

into a microprocessor. They tend to be very simple,

performing only one function – robots may move toward a light

source, for example, or away from a heat source. As such,

they’re a way of physically modelling the behaviour of simple

creatures, motivated by primal things like a need for food, water,

or WiFi.

This flapping, solar-powered dragonfly was built by Jack

Spiggle, aka NanoRobotGeek, using the guts of a broken radio-

controlled flying toy dragonfly. Most of it has been replaced with

a snazzy free-form soldered circuit made from brass rods.

The dragonfly stores energy from a solar panel in capacitors

until it reaches 4 V, at which point it dumps it into the wing-

flapping mechanism. You can see capacitors soldered into the

dragonfly’s tail – these add up to 2200 μF, which is only enough

to give the wings a slight flicker. To add extra power, Jack hid

an extra 4700 μF capacitor in a hole drilled into the wooden base

under the solar panel. This combined 6900 μF is enough storage

to power the wings through a whole cycle.

Right

We’ve tried free-form

soldering before,

and it’s harder than it

looks to get anything

that works, let alone

that looks good

8

SPARK

9

Top Projects

REGULAR

10