Table Of ContentProduct AIRSTREAM™

40UV,UH050-200

Data

Unit Ventilators

500 to 2000 Nominal Cfm

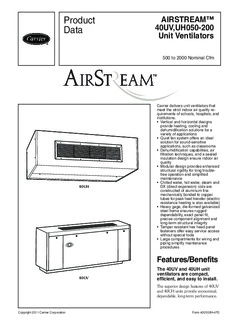

Carrier delivers unit ventilators that

meet the strict indoor air quality re-

quirements of schools, hospitals, and

institutions.

• Vertical and horizontal designs

provide heating, cooling and

dehumidification solutions for a

variety of applications

(cid:129) Quiet fan system offers an ideal

solution for sound-sensitive

applications, such as classrooms

(cid:129) Dehumidification capabilities, air

filtration techniques, and a sealed

insulation design ensure indoor air

quality

(cid:129) Modular design provides enhanced

structural rigidity for long trouble-

free operation and simplified

maintenance

(cid:129) Chilled water, hot water, steam and

40UH DX (direct expansion) coils are

constructed of aluminum fins

mechanically bonded to copper

tubes for peak heat transfer (electric

resistance heating is also available)

(cid:129) Heavy gage, die-formed galvanized

steel frame ensures rugged

dependability, exact panel fit,

precise component alignment and

long-term structural integrity

(cid:129) Tamper resistant hex head panel

fasteners offer easy service access

without special tools

(cid:129) Large compartments for wiring and

piping simplify maintenance

procedures

Features/Benefits

The 40UV and 40UH unit

ventilators are compact,

40UV efficient, and easy to install.

The superior design features of 40UV

and 40UH units provide economical,

dependable, long-term performance.

Copyright 2011 Carrier Corporation Form 40UV,UH-4PD

Features/Benefits (cont)

Indoor air quality Double sloped condensate drain Front access panels are secured

pan can be configured for right-hand with hex-head fasteners to provide

The combination of features found in

or left-hand drain connection in the tamper-resistance while maintaining

40UV and 40UH unit ventilators en-

sures that only clean, healthy, condi- field. Drain connection size 7/8 in. OD easy maintenance and service access.

tioned air is delivered to the occupied copper. Efficient direct-drive motor prevents

space. Ventilation rate is certified per Cooling coil has a full-depth design. alignment problems. Blowers share a

AHRI (Air Conditioning, Heating, and When combined with available face common hollow shaft connected to the

Refrigeration Institute) Standard 840 and bypass damper, the coils prevent motor with a resilient coupling.

by an independent laboratory. the build-up of humidity in the room, Steel blower housings are securely

One-piece filter cleans the air before even during part load conditions. mounted to a die-formed galvanized

it is introduced into the room. Unit is Precision fan system provides quiet steel blower deck.

shipped with a 1-in. throwaway filter operation in environments where Self-aligning bearings, vibration

and can accept permanent or renew- sound control is critical, such as isolating motor mounts and flexi-

able media filters. Filter track may be classrooms. Sound level is certified by ble drive shaft coupling isolate the

adjusted to accept field-supplied 2-in. an independent laboratory per AHRI rotating components from the rest of

filter. Standard 350. the unit to ensure quiet vibration-free

Combination outdoor/return air Die-formed, heavy-gage steel operation.

damper, standard on all units, pro- cabinet provides secure, dent- Mechanically bonded aluminum

vides positive control of ventilation air. resistant protection for internal com- fin coils provide improved heat trans-

Extruded aluminum damper is insulat- ponents. Cabinet exterior has a fer with corrosion and vibration resis-

ed with closed cell foam insulation. baked-on polyurethane powder-coated tance. Copper tubes are standard.

finish for corrosion resistance and en-

hanced appearance.

UNIT VENTILATOR CONSTRUCTION

DIRECT DRIVE FAN

a40-1671 MOTOR

DIRECT DRIVE FAN

MOTOR

SERVICE SWITCH*

FUSE(S)*

FAN SPEED

SWITCH*

DIFSUCSOEN(NSE)*CT

SWITCH*

FAN SPEED

SWITCH*

DISCONNECT

SWITCH*

DAMPER

ACTUATOR COMBINATION OA/RA

DAMPER CONDENSATE

DRAIN CONNECTORS

** SSADCEeAEeTMU 44AP00TEUOURVRV,U,HUC HINO SMInTBAsIDtLNaALAlAMlTaTIPOtIOiEoNRNn O,, SAST/RtAaARrTt--UUPCp OAaNNnDDd E SSNEeSRArVvTIiECcEe IINnSsTtrRuUcCtiToInOsN Sfor additional information.

ADDITIONAL INFORMATION. DRAIN CONNECTORS

*See 40UV,UH Installation, Start-Up and Service Instructions for additional information.

2

Enhanced performance and electric heat is turned on. Electric motor is standard on all size 200 units

safety heat is turned off in case of high-heat (2000 cfm). The ECM motor is also

conditions. provided for units with high static pres-

Draw-thru blower arrangement

sure application or units with the UV

distributes air across entire coil face for Economical operation

Open controller option or units with

uniform discharge temperatures.

The 40UV and 40UH Series unit field supplied and installed controls.

Draw-thru design also eliminates hot

ventilators not only have low initial Motors are mounted out of the air-

spots in electric heat coil to maximize

costs, but they also save money by stream so they are not subject to coil

heating element life.

reducing installation expense and heat, extending the life of the motor.

Efficient direct drive helps to main-

providing long-term energy-efficient

High-efficiency, precision-

tain low operating costs and also re-

performance.

balanced blowers minimize air tur-

duces maintenance requirements.

Quick installation provided by built- bulence, surging and vibration to

Wide selection of factory-installed

in levelers, drain pan connections on minimize operating expenses.

coils includes chilled and hot water,

both ends of the unit, and reversible

Mixing dampers control the blend of

DX, steam, and electric resistance heat

coil hand without unit modification.

outside air and room air to achieve

coils.

Permanent split capacitor (PSC) comfort levels. When the outside air is

Motor and control protection is

motors are standard on size 50 to suitable, outside air dampers can fully

provided by cartridge fuses. Units are

150 units (500 through 1500 cfm). open to provide free cooling.

ETL listed to UL Standard 1995.

Electronically commutated (ECM) Fewer moving parts lower operating

Safety cutouts and interlock

blower motor option saves energy costs by enhancing reliability and mak-

switches ensure safe performance.

and overload protection with automatic ing service easier.

Fan must be operating before optional

reset ensures reliability. The ECM

Table of contents

Page

Features/Benefits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Model Number Nomenclature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-9

AHRI Capacity Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Options and Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-13

Base Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14-24

Accessory Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25-45

Selection Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Performance Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46-77

Electrical Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78-84

Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85-89

Guide Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90-94

3

Model number nomenclature

BASE UNIT MODEL NUMBER

F 1 C B F G B F A 1 A

SEE NEXT PAGE

FOR REMAINDER

OF MODEL

NUMBER

F – UH/UV Current Design

NOMENCLATURE

Paint Options

(1-in. Thick)

Temperature Control Type

A – No Controls

D-H – DDC Ready

J-3 – Carrier UV Open Controls

X – Factory-Installed Controls by Others

Inlet Arrangements Outdoor Air Damper

Horizontal Units 1 – Standard Damper Assembly

A – Bottom RA, Top OA D – Rear RA, Top OA 2 – Standard Damper Assembly with Locking Quadrant

B – Bottom RA, Rear OA E – Rear RA, Rear OA 3 – Cold Weather Damper Assembly

C – Bottom RA, No OA F – Rear RA, No OA 4 – Cold Weather Damper Assembly with Locking Quadrant

5 – No Outdoor Air Damper (Recirculation Only)

Vertical Units

165/8 in. 165/8 in. Face and Bypass Damper

CABINET, CABINET

DESCRIPTION 1 – No Damper

FRONT DRAFT STOP

RA RA 2 – Face and Bypass Damper

A L Rear OA, Open Piping Tunnel

B M Rear OA, Closed Piping Tunnel Fan Motor Selection

C N Bottom OA, Open Piping Tunnel 1 – PSC - Standard

D O No OA, Open Piping Tunnel 2 – ECM - High-Efficiency Motor

5 – ECM - Variable Speed Motor

217/8 in. 217/8 in.

CABINET, CABINET Discharge Air

DESCRIPTION

FRONT DRAFT STOP Horizontal Units

RA RA A – Front Discharge Bar Stock Grille*

E P Rear OA, Piping Passage Unit B – Front Discharge Grille with Screen*

F R Rear OA, Full Adapter Back C – Front Discharge Duct Collar (No Grille)*

G S Top OA, Full Adapter Back D – Front Discharge Duct Collar with Plenum (No Grille)†

E – Front Discharge Double Deflection Grille with Plenum†

H T Bottom OA, Open Adapter Back

F – Bottom Discharge with Double Deflection Grille**

I U No OA, Open Adapter Back

J W 21/2 in. Step Down Pipe Pass Adapter Back Vertical Units

K Y 21/2 in. Step Down Full Adapter Back A – Top Discharge Bar Stock Steel Grille

B – Top Discharge Grille with Screen

C – Top Discharge Duct Collar (No Grille)

See next page for legend and footnotes. A40-1672

4

BASE UNIT MODEL NUMBER (cont)

40 UV F 3 P 1 A A B 1 2 2 M 0 J 1 C B F G B F A 1 A

Warranty

SEE PREVIOUS PAGE A – One Year

FOR REMAINDER

Filter Option

OF MODEL 1 – 1-in. Throwaway Filter

NUMBER 2 – 1-in. Renewable Filter

3 – 1-in. Permanent Filter

NOMENCLATURE 4 – 2-in. Pleated Filter

Drain Pan Option

A – Galvanized Drain Pan

B – Stainless Steel Drain Pan

Cooling Valve Piping Package

A – None

B-E – Packages used with 2-Way Valve

F-J – Packages used with 3-Way Valve

X – 2 or 3-Way Special Piping Package

Cooling Valve / Actuator

A – None

0 – Not Used B-G – 3-Way Modulating Valve / Actuator

H – 3-Way, 2-Position Valve††

Power Supply / Disconnect J-O – 2-Way Modulating Valve / Actuator

J – 115-1-60 (Standard) P – 2-Way, 2-Position Valve††

K – 208-1-60

Cooling Coil Type

L – 240-1-60

A – None

M – 277-1-60

F-L – Cold Water Same End Connections

5 – 208-3-60 (3-Wire)

8,9 – C/W High Capacity Same End Connections

6 – 240-3-60 (3-Wire)

Y,Z,2,3 – Direct Expansion

7 – 460-3-60 (3-Wire)

Heating Valve Piping Package

Coil Arrangements A – None

1 – H/W Position 1, C/W Position 2 (PreHeat) B-E – Packages used with 2-Way Valve

2 – H/W Position 2, C/W Position 1 (ReHeat) F-J – Packages used with 3-Way Valve

X – 2 or 3-Way Special Piping Package

Heating Coil Type

A – None Heating Valve / Actuator

B-J – Hot Water Same End Connections A – None

M-R – Steam Same End Connections B-G – 3-Way Modulating Valve / Actuator

S-W – Steam Opposite End Connections H – 3-Way, 2-Position Valve††

3-6 – Electric Heat Right Hand Coil Connection J-O – 2-Way Modulating Valve / Actuator

P – 2-Way, 2-Position Valve††

1-6 – Steam, 2-Way Modulating Valve / Actuator

P – Steam, 2-Way, 2-Position Valve

LEGEND *Available for 301/2 in. horizontal units only.

DDC — Direct Digital Controls †Available for 36 in. (40 in. for size 200) horizontal units only.

ECM — Electronically Commutated Motor **Available for 40 in. (44 in. for size 200) horizontal units only.

OA — Outside Air ††Face and bypass units only.

PSC — Permanently-Split Capacitor

RA — Return Air

A40-1673

5

Model number nomenclature (cont)

STORAGE CABINET PART NUMBERS*

SC 21 1 F3 D S 2 42 1

Storage Cabinet Interior

1 — Standard Single Shelf

2 — Second Shelf

Depth

3 — Tote Trays

21 — 21-7/8 in.

16 — 16-5/8 in.

Color

Standard Custom

Model 41 — Beige 46 — White

1 — Standard 42 — Pola r Ice CM — Custom Match

2 — Standard with Pipe Chase 43 — Gray

4 — Standard with Louvered Inlet and Outlet

5 — Standard with Aluminum Extrusion Length

Draft Stop Inlet

2 — 2 ft

6 — Standard with Louvered Inlet and Aluminum

3 — 3 ft

Extrusion Outlet

4 — 4 ft

7 — Shallow Shelf with Pipe Chase†

5 — 5 ft

8 — Shallow Shelf with Louvered Outlet†

9 — Shallow Shelf with Louvered Inlet and Aluminum

Extrusion Outlet†

Material Thickness

S — Standard 18 gage

To ps

H — Heavy Duty 16 gage

F1 — White Formica

F2 — Black Formica

F3 — Fog Formica Doors

F4 — Folkstone Formica O — Open

F5 — Almond Papyrus Formica D — Doors

F6 — Almond Formica L — Doors with Lock

F7 — Pumice Formica

CF — Custom Formica

TX — Charcoal Texture Paint

NT — NoT op

a40-1659

FILLER SECTION PART NUMBERS*

SC F2 21 F3 42

Storage Cabinet

Accessory Color

F1 — Filler Panel 12 in. Standard Cu stom

F2 — Filler Panel 18 in. 41 — Beige 46 — White

F3 — Filler Panel 24 in. 42 — Polar Ice CM — Custom Match

BA — Back Angle 43 — Gray

CF — Corner Filler

EP — End Panel Tops

F1 — White Formica

F2 — Black Formica

Depth F3 — Fog Formica

21 — 21-7/8 in. F4 — Folkstone Formica

16 — 16-5/8 in. F5 — Almond Papyrus Formica

F6 — Almond Formica

F7 — Pumice Formica

CF — Custom Formica

TX — Charcoal Texture Powder Coated Steel

NT — NoT op

00 — End Panel

*To order, contact your Carrier Sales representative.

†Available for 165/8 in. depth only.

6

DRAFT STOP PART NUMBERS*

DS 24 FT S P 4 42

Draft Stop

Color

Standard Custom

41 — Beige 45 — Brick Red

Height

42 — Polar Ice 46 — White

12 — 12 in. 43 — Gray CM — Custom Match

20 — 20 in.

24 — 24 in.

Length

2 — 2 ft

Grille Type 3 — 3 ft

FT — Flat Top (Louvered) Inlet 4 — 4 ft

BG — Aluminum Extrusion Bar Grille Inlet 5 — 5 ft

6 — 6 ft

Material Thickness Back Panel

S — Standard 18 gage P — Partial Back Panel

H — Heavy Duty 16 gage F — Full Back Panel

DRAFT STOP ACCESSORY PART NUMBERS*

DS T3 20 42

Draft Stop

Color

Standard Custom

41 — Beige 46 — White

42 — Polar Ice CM — Custom Match

Accessory 43 — Gray

T3 — Trim Strip 3-1/2 in.

T7 — Trim Strip 7-1/2 in.

OC — Outside Corner Height

IC — Inside Corner 12 — 12 in.

EL — End Cap Left 20 — 20 in.

ER — End Cap Right 24 — 24 in.

*To order, contact your Carrier Sales representative.

7

Model number nomenclature (cont)

PIPE ENCLOSURE PART NUMBERS*

PE CB 4 11 S 45 42

Pipe Enclosure Color

Standard Custom

Model

41 — Beige 46 — White

CB — Closed Bottom

42 — Polar Ice CM — Custom Match

43 — Gray

Depth

4 — 4 in.

Length

5 — 5 in.

10 — 1 ft 30 — 3 ft

15 — 1.5 ft 35 — 3.5 ft

Height

20 — 2 ft etc., in 1/2 ft increments up to

08 — 8 in.

25 — 2.5 ft 80 — 8 ft

11 — 11 in.

14 — 14 in.

Material Thickness

20 — 20 in.

S — Standard 18 gage

H — Heavy Duty 16 gage

a40-1660

PIPE ENCLOSURE ACCESSORY PART NUMBERS*

PE CB T3 4 11 42

Pipe Enclosure Color

Standard Custom

41 — Beige 46 — White

Model 42 — Polar Ice CM — Custom Match

CB — Closed Bottom

43 — Gray

Accessory Height

T3 — Wall Trim 3-1/2 in. wide 08 — 8 in.

T7 — Wall Trim 7-1/2 in. wide 11 — 11 in.

OC — Outside Corner 14 — 14 in.

IC — Inside Corner 20 — 20 in.

EL — End Cap Left

ER — End Cap Right

Depth

4 — 4 in.

5 — 5 in.

a40-1661 *To order, contact your Carrier Sales representative.

*To order, contact your Carrier Sales representative.

8

SINK AND BUBBLER PART NUMBERS*

BC SS S DB 42

Sink and Bubbler

Tops

F1 — White Formica

Color

F2 — Black Formica

Standard Custom

F3 — Fog Formica

41 — Beige 46 — White

F4 — Folkstone Formica

42 — Polar Ice CM — Custom Match

F5 — Almond Papyrus Formica

43 — Gray

F6 — Almond Formica

F7 — Pumice Formica

CF — Custom Formica

Sink and Bubbler

SS — Stainless Steel

DB — Double Bowl (bowl with bubbler & bowl with

faucet), ADA Approved Fixtures

Material Thickness

SB — Single Bowl (bowl with bubbler & faucet),

S — Standard 18 gage

A DA Approved Fixtures

H — Heavy Duty 16 gage

ADA — Americans with Disabilities Act

TOUCH-UP PAINT PART NUMBERS*

TU SP 42

Touch Up

Color

Standard Custom

41— Beige 46 — White

Paint Type 42 — Polar Ice CM — Custom Match

SP — Spray Paint 43 — Gray

*To order, contact your Carrier Sales representative.

9

AHRI* capacity ratings

SENSIBLE VENTILATION

NOMINAL ACTUAL TOTAL

40UV,UH UNIT SIZE CAPACITY RATE

CFM CFM (Btuh)

(Btuh) (%)

050† 500 490 8,300 6,400 80

075 750 750 19,400 12,900 80

100 1000 1000 26,300 19,100 80

125 1250 1210 33,500 23,600 80

150 1500 1500 40,200 28,100 80

200** 2000 2010 65,000 42,000 80

*Air Conditioning, Heating, and Refrigeration Institute.

†40UV only.

**40UH only.

NOTES:

1. Ratings are in accordance with AHRI Standard 840.

2. All units are equipped with a 3-row coil.

3. Water temperature rise is 10 F, with entering water temperature of

45 F.

4. Entering air temperature is 80 F dry bulb, 67 F wet bulb.

Physical data

40UV,UH

UNIT 40UV,UH 050* 075 100 125 150 200†

NOMINAL AIRFLOW (Cfm) 500 750 1000 1250 1500 2000

FANS

Quantity 1 2 3 4 5 5

Diameter (in.) 8.32 8.32 8.32 8.32 8.32 9.5

Width (in.) 8 8 8 8 8 6

40UV FILTERS

Nominal Size (in.) (1 in. thick) 91/4 x 241/4 91/4 x 361/4 91/4 x 481/4 91/4 x 601/4 91/4 x 721/4 —

Nominal Size (in.) (2 in. thick) 91/4 x 241/4 91/4 x 361/4 91/4 x 481/4 91/4 x 601/4 91/4 x 721/4 —

Quantity 1 1 1 1 1 —

40UH FILTERS

Nominal Size (in.) (1 in. thick) — 93/4 x 361/4 93/4 x 481/4 93/4 x 601/4 93/4 x 721/4 93/4 x 721/4

Nominal Size (in.) (2 in. thick) — 93/4 x 361/4 93/4 x 481/4 93/4 x 601/4 93/4 x 721/4 93/4 x 721/4

Quantity — 1 1 1 1 1

40UV SHIPPING WEIGHT**

(Approx lb)

165/8 in. Deep Unit 330 400 480 590 660 —

217/8 in. Deep Unit 340 410 490 605 675 —

40UH SHIPPING WEIGHT**

(Approx lb)

34 in. Deep Unit — 420 500 620 690 —

391/2 in. Deep Unit — 500 600 740 830 —

431/2 in. Deep Unit — 530 640 790 880 1020

471/2 in. Deep Unit — — — — — 1050

40UV INSTALLED WEIGHT**

(Approx lb)

165/8 in. Deep Unit 315 380 460 570 640 —

217/8 in. Deep Unit 325 390 470 595 655 —

40UH INSTALLED WEIGHT**

(Approx lb)

34 in. Deep Unit — 405 480 600 670 —

391/2 in. Deep Unit — 485 580 720 810 —

431/2 in. Deep Unit — 515 620 770 860 1000

471/2 in. Deep Unit — — — — — 1030

COIL WATER WEIGHT

1.0 1.5 2.0 2.4 2.7 2.7

(Approx lb per row of coil)

COIL CONNECTIONS (in. OD) Return Supply

Water Coils with 1 to 5 Rows 7/8 7/8

Steam Coils (All Units) 7/8 11/8

Suction Liquid

DX Coils 7/8 3/8

CONDENSATE DRAIN 7/8

LEGEND *40UV only.

DX — Direct Expansion †40UH 43 1/2 and 47 1/2 in. deep units only.

**Weight based on damper-controlled unit with 5-row coil and factory-

installed controls.

10

Description:and 40UH units provide economical, dependable, long-term performance. AIRSTREAM™. 40UV,UH050-200. Unit Ventilators. 500 to 2000 Nominal