Table Of ContentVol. 37, No. 1

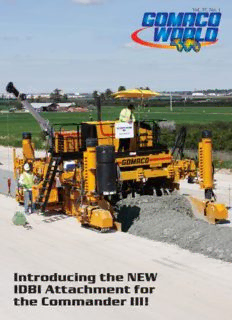

Introducing the NEW

IDBI Attachment for

the Commander III!

Vol. 37, No. 1

GOMACO

President and CEOGary L. Godbersen

Vice Presidents

Accounting Sharon K. Godbersen

Administration & Finance Richard E. Smith

Engineering/Research & Development

Kevin L. Klein

ManufacturingGrant Godbersen

3 GOMACO VERSATILITY SHOWCASED ON I-64 PROJECT Worldwide Sales and Marketing

Kent Godbersen

– Fred Weber, Inc., and Millstone Bangert, Inc.

General Manager of Manufacturing

7 SLIPFORMING CANAL IN NORTHERN TURKEY Dan Soellner

– Basat Elektrik Uretim & Tic. Ltd. Sti. Sales United States and Canada

Sales Manager Bob Leonard

9 DOUBLE VARIABLE BARRIER WALL ON ILLINOIS’ I-55 Sales Coordinator Brad Zobel

Assistant Sales Coordinator Mike Leinbaugh

– P.T. Ferro Construction Company

United States and Canada

11 PAVING 99 LANE MILES (159 KM) WITHOUT A GRIND District Managers

Brad Barkema – N. Central

– The Scruggs Company

Jim Hayward – Western

Kendall Kelly – S.W.

14 A HIGH-SPEED CONNECTION BETWEEN FRANCE & SPAIN Vinnie Miller – S.E.

– Eiffage Travaux Publics Len Rettinger – N.E./Central

International Sales

18 COMMANDER III POWER ON A MONO PROJECT Director Bryan Schwartzkopf

– Petra Contracting Coordinator Randy Bean

International Regional Manager

20 NEW GOMACO INNOVATIONS (Cover photo CG-030918 D14) Tim Nash – Asia Pacific

– New IDBI Attachment for the Commander III and More! Steve Bowman – Latin America

GOMACO International Ltd.

23 AROUND THE WORLD Managing Director Rory Keogh

Sales Managers John Bowden

& Andy Linham

7 11 14 20

Service Department

Manager Dennis Ernst

Service Desk DeWayne Krayenhagen

& Doug Comstock

Parts Manager John Kallin

Parts Desk Dan Ellerbusch,

Jeff Stevenson & Dean O’Tool

GOMACO University Training Center

Director Dennis Clausen

Please visit our Web site at http://www.gomaco.com

Assistant Director Rod Schneider

GOMACO Worldmagazine at http://www.gomaco.com/gomacoworld

GOMACO WorldEditor Kelly Krueger at [email protected] GOMACO Worldis produced by the

GOMACOAdvertising Department.

GOMACO Worldis published by GOMACOCorporation to inform readers of applied construction

technology utilizing GOMACOequipment as well as innovations and concerns in the construction Manager Randy Bach

industry throughout the world. All rights reserved. The contents of this publication may not be Marketing Coordinator Micki Rettinger

reproduced either in whole or in part without the consent of copyright owner. Printed in U.S.A. GOMACO WorldEditor Kelly Krueger

© 2009 GOMACOCorporation (06 CFX). All stories written by the editor unless otherwise noted.

Communications Specialist Thomas R. Grell

Address all communications to GOMACOWorldEditor. If you do not receive GOMACOWorld, Communications Specialist Bobbi L. Wonder

and would like a complimentary subscription, please contact GOMACO Corporation, PO Box 151, Advertising Coordinator Carrie J. Odgaard

Ida Grove, IA, 51445, USA, 712-364-3347 or e-mail [email protected].

Photo Lab Don Poggensee

GOMACO Corporation's Quality Management System Is

ISO 9001:2000 Certified By The American Systems Registrar.

Quality Policy: We Shall Meet Or

Exceed Our Customers’ Expectations.

GOMACO Versatility Showcased on I-64 Project

One of the most unique projects in slipformed by GOMACO equipment. Paving for Fred Weber, said. “That

Missouri history is currently in its Fred Weber and Millstone Bangert machine will do anything you ask it to

second phase on Interstate 64 through have brought their fleet of GOMACO do. It’s just amazing what it can do, as

St. Louis. The design-build project, the equipment onto the project. That fleet small as it is.”

city’s first, is a complete replacement includes three 9500 trimmer/placers,

Paving the Mainline –

of approximately 10 miles (16 km) of an RTP-500 placer, four Commander III

But let’s start at the beginning of

the interstate right through the heart four-tracks, and a GHP-2800 paver.

the project and the removal of the

of the city. One-half of the 10 miles It’s a lot of equipment, but the variety

existing roadway. All of the material

(16 km) is completely shut down to of applications the equipment is

on the project was recycled. The

traffic while work takes place. The slipforming is astounding.

concrete was crushed and used again

unprecedented move is taking years The Commander IIIs are

for the base material. The base for the

off the completion date and creating a slipforming shoulders, medians,

I-64 project consists of 10 inches

safer environment for the construction variable-width ramps, inside median

(254 mm) of six inch (152 mm) minus

workers. barrier wall, outside barrier wall,

rock, capped with two inches (51 mm)

The project is being built by a retaining wall, roundabouts, bridge

of Type 5 rock. The top layer is

consortium called Gateway parapet, truck lanes, half-shaped

trimmed to the accurate, final grade

Contractors, which involves barrier wall against MSE

with a GOMACO 9500 with an 18 foot

contractors Granite Construction; (mechanically-stabilized earth)

wide (5.5 m) trimmerhead.

Fred Weber, Inc.; and Millstone wall, and moment slabs for the

Millstone Bangert is responsible

Bangert, Inc. The two-year sound wall. That’s over 10 different

for all of the mainline paving on the

project involves 200,000 cubic applications that one machine is

project and are using their GOMACO

yards (152,912 m3) of concrete. capable of slipforming.

four-track GHP-2800 paver. Project

All of the concrete will be “In my opinion, the Commander III

smoothness specifications require a

is the best machine around and you

reading of under 30 and Millstone

can’t beat it for versatility,” Jim

Bangert is consistently running

Jackson, Operations Manager of

D4

G-100819

C

ger

Krue

Kelly

by

Photos

A GOMACO 9500 feeds concrete onto the belt of a four-track Commander III slipforming barrier wall on a project in St. Louis.

3

“In my opinion,the Commander III is the

best machine around and you can’t beat

it for versatility,”Jackson said.“That

machine will do anything you ask it to

do.It’s just amazing what it can do,as

small as it is.”

between 10 and 12 on the zero-blanking band.

Smoothness, according to Ron Dibler, Millstone

Bangert’s PavingSuperintendent, begins with

the base.

“Good ride is a process that begins from the

ground up,” Dibler said. “You have to have good

string, consistent mix and try to keep the paver D14

mtahnoodvu rignuhgn, witsh ieath pg moavoiednri ms’so ultirmda c tskrtisom.p”ms. eMd obsats iem tpo opratavnet on FT-100801

A 9500 trims grade for the mainline portion of the paving project. The

Each paving pass with the GHP-2800 is nine or

trimmer is equipped with an 18 foot (5.5 m) wide trimmerhead.

10 inches (229 to 254 mm) thick and 25 feet (7.6 m)

wide. They’re building four new lanes of interstate,

Retaining Wall –

for both the eastbound and westbound sides. Paving

production averages between 2500 to 3000 cubic

yards (1911 to 2294 m3) per day.

All of the concrete for the project is being

supplied by two on-site batch plants. Concrete is

delivered to the paving site by tandem-axle dump

trucks. The concrete is a Missouri Department of

Transportation (MDOT) approved mix with an

average slump of 1.5 inches (38 mm).

All of the Wall –

Slipping the Outside Barrier Wall – The profiles D1

fsoimr tilhaer ,i nbusitd teh aen odu tosuidtsei dbea rbraierrr ihera sw saolulsn adr ew vaellry G-040813

C

mounted to the top of it. ACommander IIIis used d

to slipform a moment slab with a rebar grid. The m Hel

steel for the wall is tied to the rebar grid in the by To

moment slab. With the steel in place, the spacing for Photo

the sound wall is meticulously plotted and the Two rebars at a time are hydraulically inserted into the top of this barrier.

anchoring bolts for each post are carefully set.

Another wall will be slipformed on top to form a retaining wall on the project.

“The sound wall posts have to be put in the

exact location, because each panel is made to fit a

certain area,” Dibler said. “After the cages are built,

we dry run the steel to make sure everything is

going to work and it’s all set to the right height.”

The concrete trucks dump their loads into an

RTP-500, which then feeds the belt on the

Commander III. The central mix concrete, according

to Dibler, gives their concrete more consistency and

allows them to run a drier mix for their barrier

work.

Behind the Commander III, workers have to

locate the anchoring bolts for the sound wall, dig

D3

tinhsetmal loeudt aafntedr etxhpe ocsoen tchreetme hsoa st hceu rpeods.t s can be G-100843

Center Median Barrier –A9500 placer feeds C

d

another four-track Commander III as it slipforms Hel

m

the variable-height center median barrier. The To

h7.e2i5g hfet eotf ( t2h.2e mw)a.l l varies from four feet (1.2 m) to Photo by

A roundabout on the project was slipformed 20 feet (6.1 m) wide with

4 integral curb around a 45 foot (13.7 m) radius.

“We’ve been able to slipform variable

Non-variable Barrier –

pavement widths very easily,and that’s

been a big help on this project,”Dibler

said.“The new roller frame on the

Commander III and the transition

sensors go right through the width

changes without a problem.”

The non-variable height barrier has 10

longitudinal bars fed into the front of the mold for

wall reinforcement. The variable-height barrier is

slipformed over a steel cage in the lower half of the

wall. They are inserting six longitudinal bars into

D19 the front of the mold for the top section of the wall.

G-100820 costR-seatvaiinngin mg eWasaulrle – oTnh teh ec opnrsoojertcitu bmy esntagciknienegr etdw ao

C

Ten longitudinal bars are fed into the front of the mold on the slipformed walls on top of each other instead of

putting in MSE wall. The first retaining wall varies

Commander III for the non-variable barrier wall.

in height between three feet (0.9 m) and six feet

(1.8 m). Two rebars are hydraulically inserted

vertically into the 24 inch (610 mm) wide top of the

wall and vibration is applied to the rebar during

insertion. The wall is allowed to cure, and then

backfilled. The roadway is brought up to grade, and

then another section of wall is slipformed on top of

the existing wall.

“The slipformed retaining wall replaces MSE

walls shorter than nine feet (2.7 m) in areas that

would retain dirt,” Dibler explained. “Rather than

building a costly MSE wall, we were able to

slipform retaining walls.”

Side-mounted Shoulder and Medians –

All of the shoulder and medians on the project

are slipformed with a side-mounted mold on the

G-100822 D3 C((11o..82m mtmo) a3 wn mdide),er .oI SrII h8. o.M5u efldedeeitar sn( 2sv. 6aa rrmye )sf rliiofp mtfho efrormeu erids t oas i1bx0a f refreeieet tr

C

The Commander III is equipped with a variable-height mold for wall on it. Zero-clearance paving against the MSE

slipforming both the variable and non-variable center median barrier. wall was accomplished after modifying their mold.

“We had an idea of moving the sideform

cylinders and mounting structure from the outside

of the mold to the inside of the mold and

minimizing the thickness of the sideform,” Dibler

said. “We were able to get that down to about two

inches (51 mm), which allows us to slipform closer

to the walls, and that’s been a big help on this job.”

Variable-width ramps with the V2 mold –

Two of the Commander IIIs on the project are

equipped with V2 variable-width molds. The V2s

have the optional auto-width adjustment package to

allow the mold to make on-the-go width changes

and produce a tapered slab. Asecond stringline is

set to follow the desired tapered slab, and sensors

on the paver use that second stringline to control

the cylinders that extend or retract the frame and

CG-100825 D13 sstriydasnetes-smithi ioofntn t ahanued tmo tmhoelad tm.i cTo whldeh aeodnpj euarpsatptsor troo as citmhheipn nlgye twphu ep twsa vtidhinetgh

The V2 mold is making on-the-go width changes from 15 feet (4.6 m)

down to 12 feet (3.7 m), and 18 feet (5.5 m) down to 12 feet (3.7 m). 5

D13

G-100838

C

The Commander III slipforms barrier next to a section

of already finished sound wall.

D14 D8 D3

G-100833 G-100833 G-100836

C C C

The first step to the sound wall is slipforming a moment slab. The slab features extra steel reinforcing slipformed into the concrete. The

steel caging for the barrier wall is anchored to the steel in the slab. Extra supports for the sound wall are incorporated into the wall’s

steel cage. The posts that support and hold the sound wall panels are then bolted to the supports after the concrete wall has cured.

width automatically. You don’t have to worry about radius. Fred Weber decided to pave the

Width changes on the ramps anything else. It gives us such first roundabout in two separate pours.

include transitions from 15 feet (4.6 m) flexibility and different options. It’s The first was 10 feet (3 m) wide and

down to 12 feet (3.7 m) wide, and just a very smooth transition.” the second was the same width with a

18 feet (5.5 m) down to 12 feet (3.7 m) It allows them to pave at different three inch (76 mm) mountable curb.

wide. The transitions are made on-the- widths, with one machine, all in the “The tight radius intimidated us a

go, with no need to stop and adjust same day. On a project like this, it’s a bit on the first roundabout,” Jackson

the paver width. necessity and a huge time savings. said. “The second one though, we

“This is something I’ve been “We’ve been able to slipform decided to pour the full 20 foot (6.1 m)

looking forward to for a long time,” variable pavement widths very easily, with the curb on it. It worked out just

Jackson said. “We’ve always had to and that’s been a big help on this fine, and we accomplished it all in one

stop paving and add or take out a project,” Dibler said. “The new roller pour, instead of two.”

section, and that takes time. Then, frame on the Commander III and the To finish out the roundabout, a

when we first got our V2 mold, we transition sensors go right through the lane was slipformed inside of its

had to set our stringline like normal width changes without a problem.” radius. The lane, which is used to

and paint a line where we wanted our assist trucks through the roundabout,

Roundabouts –

transition. Aworker would stand was nine inches (229 mm) thick, and

Another cost-saving measure on

there with the remote in hand and try 10 feet (3 m) wide with a six inch

the project included building two

to follow that line manually. (152 mm) vertical curb.

roundabouts instead of entrance and

“Now with this new package The I-64 project is scheduled to

exit ramps. The 20 foot (6.1 m) wide,

and the extra cylinder and stroke, have traffic back on the finished

eight inch (203 mm)thick roundabouts,

we can set our second stringline and second phase by the end of this year.

with integral curb on one side, had to

the transitions follow the stringline. It’s a deadline the consortium is

be built around a 45 foot (13.7 m)

confident they’ll make.

6

D18

W-090816

H

Moser

Ric

by

Photos

The GP-2600 with a front-mounted chain trimmer slipformed a new canal between Amasya and Tasova in northern Turkey.

Slipforming Canal in Northern Turkey

Water has always been a precious paver to slipform three kilometers 150 millimeters (5.9 in) thick. The

commodity in the Amasya Province of (1.9 miles) of new canal between the GP-2600 has the capabilities of

northern Turkey. Afamous canal, the cities of Amasya and Tasova. paving canal profiles between six to

Ferhat Water Canal, was first carved The new canal has a top width 9.9 meters (19.7 to 32.5 ft) wide.

into the mountains during the late of 22.3 meters (73.2 ft), bottom width At the start of the project,

Hellenistic Age and early Roman of 6.7 meters (22 ft), and 9.3 meter over 2.5 million cubic meters

Period, approximately 2000 years ago. (30.5 ft) side slopes that are (88,286,188 ft3) of material had to be

It was constructed using the water

balance system by opening tunnels on

the carved rocks and forming vaulted

walls using the natural slope of the

land to make the water flow to the

ancient city of Amasya.

Water is still a precious

commodity in northern Turkey and

the modern city of Amasya. The city is

home to over 350,000 people. The

entire province of Amasya is very

agricultural and is famous for its

apple crops. They also produce

tobacco, peaches, cherries and okra.

Amore modern method of

building canals is currently underway

near the city. Basat Elektrik Uretim & D17

TTuicr.k Letyd, .i sS tui.s,i nbags ae dG oOuMt oAfC IOsta GnPbu-2l6,00 W-090817

H

The GP-2600 paved each of the canal slopes are 9.3 meters (30.5 ft) wide.

77

D3

W-090818

H

Concrete was discharged into the concrete feeding system with an auger and baffles that fed it down the slope of the canal.

excavated to build the new canal. A trimming up to 50 millimeters (2 in) of into a concrete distribution system

fleet of crawler dozers and excavators fine grade material. mounted to the front of the paver. The

worked on the project getting the Concrete for the canal was distribution system is an auger system

canal to the proper profile. produced at an on-site mobile batch with baffles that run along the slope

The GP-2600 was equipped with plant. Ready-mix trucks delivered the of the canal. An auger moves the

a chain trimmer to trim down any concrete to the paver. Slump averaged concrete down the slope, while the

high spots in the crushed-gravel 50 millimeters (2 in). baffles collect the concrete to keep it

grade. The trimmer is capable of The ready-mix trucks discharged from sliding down to the bottom of

the 1.5:1 slope of the canal wall.

Behind the paver, a transverse

joint cutter and two longitudinal disk

wheel cutters cut the joints. Each is

spaced three meters (10 ft) apart and

the joint, itself. is 10 millimeters

(0.4 in) wide. Finishers stood on a

work bridge mounted to the back of

the paver and applied a trowel finish

to the surface of the canal and around

the joints. Paving production

averaged around 170 cubic meters

(222 yd3) per hour.

Basat Elektrik’s portion of this

canal is nearly finished. They plan on

keeping their GP-2600 paver busy in

the future on more canal work on 28

different hydroelectric projects. The

D15 work will be carried out over the next

W-090818 fTiuvrek yeey.ars throughout the country of

H

The chain trimmer on the GP-2600 is capable of trimming up to 51 millimeters

8 (2 in) of fine grade material in the canal.

Double Variable

Barrier Wall on

Illinois’ I-55

P.T. Ferro Construction Company first

started work in 1964 as utility contractors in

Joliet, Illinois. Since that time, they’ve taken

on a variety of challenges as they expanded

their business. They added a GOMACO

GT-3600 curb and gutter machine in 2004

and started slipforming their own curb on

their projects.

The Illinois Department of

Transportation (IDOT) let a barrier wall

project on Interstate 55, just west of their

Joliet location. They had never slipformed

barrier wall before, but weren’t afraid of the

challenge. They consulted with their

GOMACO distributor, Finkbiner Equipment

Company, and with GOMACO engineers to

find the right machine and mold profile to

complete the 22,000 lineal feet (6706 m) of

variable height, center median barrier.

They purchased a Commander III with

a four-track barrier package assembly. The

mold was built with double variable

capabilities so each side of the wall could

be adjusted up to 30 inches (762 mm) to

meet project specifications in a single

slipforming pass.

Choosing the right machine was an

important decision in the project’s early

phase. P.T. Ferro was working under a tight

deadline for completing a portion of the

work before winter weather moved in.

“This job had an interim completion

date that included a penalty,” Phil Hess,

19 inches 19 inches President of P.T. Ferro, said. “We were

(483 mm) (483 mm)

under the gun to buy a machine, and get

2500 feet (762 m) of barrier wall slipformed

before winter set in.”

chesmm) chesmm) Their new Commander III was

D11 42-78 inches42-78 inches067-1981 mm)067-1981 mm) 32-62 inches32-62 inches813-1575 mm)813-1575 mm) (71 732 ini8n c(813 mhems) (71 7i8n c32 inmhem(813 s) 62 inches(1575 mm) 42-78 inches067-1981 mm) dpNiwan renoacolllveijluvew,e decmb trelu eabdcdtnoe narmeo lo 1nsapto5n lto. edi tnmTth ilohoeyep ne eo fe’ncisnnno ti diimOnrsaeghcpt ietpluno erfpgbtooi ejortterh hnct e2ah td 2teob a. s faytTe reaechradtieierdo rwin n agos f

Kelly Krueger CG-100732 (1(1 3-39 inches(76-991 mm) 3-39 inches(76-991 mm) (1 iwtfnroaetrei nPor“.sinOTntl.agny tF, ce”nee ret Eotrehro dite,cre s adCZaf foioaidmcl .ac amo,“ guTGaaphenilennde .e oe orrpaf e IldI rSIaauatyiprsnr egiorv fisenydtse, tnedmesnt

by on the GT-3600 and the Commander IIIare

Photos

39.25 inches 39.25 inches 9

(997 mm) (997 mm)

very similar, so it was easy for our “In a normal work day, we always Finishing work was kept to a

people to learn. Because of the exceeded our estimated production minimum with only a light broom

background we already had and the rates,”Zola said. “We were emptying finish applied behind the

ease of using the GOMACO concrete trucks every 14 minutes... Commander III.

equipment, I’d say we were up to that’s a lot of concrete. Our concrete P.T. Ferro finished their first

maximum production within a couple supplier, Welsch Ready-Mix, did an portion of interstate within the time

of days.” excellent job for us. allowed. They went back and

On the first day of their barrier “The key was getting the concrete completed the second portion of the

pour, IDOT had a review team on site to the site at the right slump, having project and impressed everyone at

to witness the slipforming. the vibrators set correctly and then IDOT with their slipformed barrier.

“They were impressed with the just having great personnel out there.” “It was a massive wall within a

quality of our wall and our total The concrete mix design was an restricted area, but it worked well for

production,” Zola explained. “And it IDOT approved mix with slump us,”Hess said. “From Marty Ahrendt

was just our first day. It only got averaging between 0.5 to 0.75 inch at Finkbiner Equipment to

better from there on out.” (13 to 19 mm). P.T. Ferro used nine GOMACO... everybody was just top

The barrier’s profile featured a straight vibrators placed at strategic notch.

39.25 inch (997 mm) wide base, and a locations in their barrier mold. They “The key, besides the equipment

19 inch (483 mm) wide top, with both also equipped their Commander III and the people, is good concrete... The

of the side walls varying in height with a 24 inch (610 mm) long concrete is crucial. Because of this

from 3.5 to 6.5 feet (1.1 to 2 m). Every conveyor extension. Zola felt the experience, we’re looking forward to

14 feet (4.3 m) of wall required a new extension made it easier to get doing more wall work with our

mixer truck, carrying a 10 cubic yard concrete from the trucks into the mold Commander III in the near future.”

(7.6 m3) load of concrete. to aid their overall production rate.

D28 D15

G-100728 G-100732

C C

P.T. Ferro’s barrier mold is built with double variable Slipforming successful wall, according to P.T. Ferro, is having

capabilities so each side of the wall can be adjusted for height. the right concrete mix design delivered at the correct slump.

D5 D13

G-100723 G-100732

C C

Stringline is set underneath the Commander III The wall has a 19 inch (483 mm) wide top, is 39.25 inches (997 mm) wide

10 and out of the way of the finishers. at the base and its sidewalls vary in height from 3.5 to 6.5 feet (1.1 to 2 m).

Description:A GOMACO 9500 feeds concrete onto the belt of a four-track Commander III slipforming barrier wall on .. the modern city of Amasya. the future on more canal work on 28 . paving train at work on the project, .. CG-090608 D20.